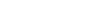

V-Belts are the most common type of drive belt used in Motors to drive

Applications

- Aerospace

- Agriculture

- Atomic Plants

- Automotobiles

- Cement

- Chemical Plants

- Construction

- Defense

- Engineering

- Food Processing

- Industrial Machinery

- Mining

- Power Plants

- Railways & Metros

- Roads and Highways

- Shipping & Marine

- Textiles

Advantages conferred to Product

Heat / Oil / Wear resistance and anti- static property.

Minimizes internal friction in the cords, improves adhesion between cords, cord to rubber and with base rubber, insulates cords and holds them in position.

High strength, excellent length stability, low elongation, high flex fatigue resistance, excellent flexibility and high resistance to shock loads in service.

Better flexibility, better belt grip on pulley grooves, high compression resistance, better dimensional stability

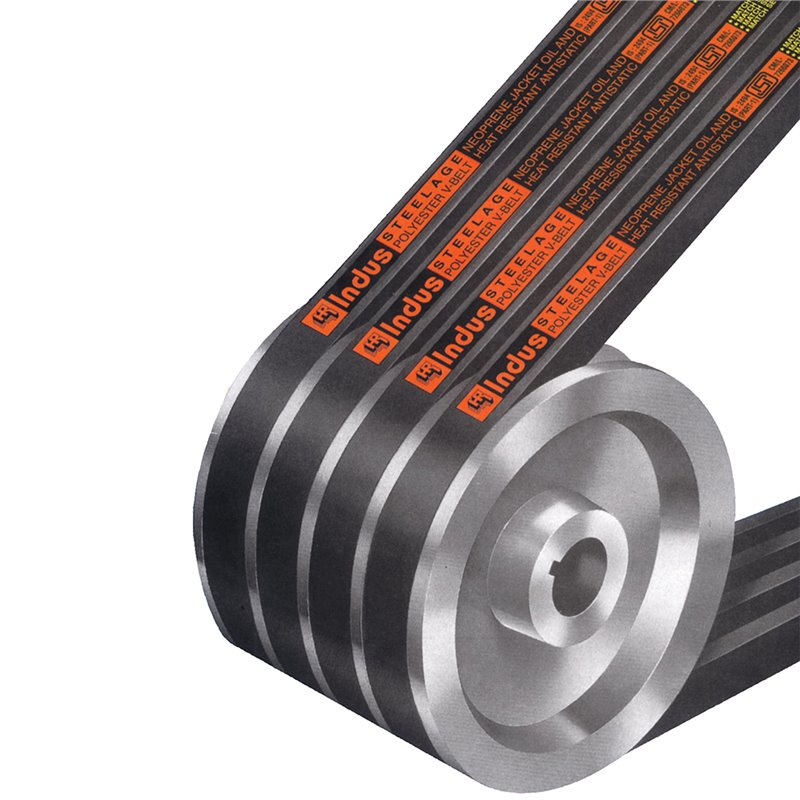

The manufacture of Vixen belts has been made possible by the use of new high tensile fibers, improve manufacturing processes and strict Quality Control. This ensures the following characteristics:

- High Performance

- Longitudinal Stability Irrespective of age

- Anti static properties

- Oil Resistance

Special Design Features

Jacket Fabric: Consists of specially designed abrasion resistant fabric.

Cushion Rubber: Consists of temperature stabilized filter rubber.

Tension Member: Consist of extra strong polyester cords which are rubberized with special compound for super bonding of filaments.

Base Rubber: Consists of firm, uniquely compounded rubber to withstand compression & to expand side ways to grip the pulley grooves while flexing over the pulley.

Applications

- Aerospace

- Agriculture

- Atomic Plants

- Automotobiles

- Cement

- Chemical Plants

- Construction

- Defense

- Engineering

- Food Processing

- Industrial Machinery

- Mining

- Power Plants

- Railways & Metros

- Roads and Highways

- Shipping & Marine

- Textiles